Safe Production of Sushi

How to make sushi the right way

-

Ingredients

Source all ingredients from reputable suppliers (e.g., raw fish, rice, seaweed etc.)

Fish used to produce sushi/sashimi dishes should be made from the freshest fish possible.

Raw fish used to make sushi/sashimi must be made from fish that is sourced from:- a supplier who can provide documentation that the fish has been caught in a fishing area where parasites are not a health hazard or exclusively reared in an environment that is free from parasites. Please note, a freezing exemption automatically applies to farmed Atlantic Salmon reared in Ireland.

or - a supplier who can provide evidence that fish that has been frozen in all parts of the product under the following conditions

- - 20 °C for not less than 24 hours;

or - - 35 °C for not less than 15 hours

Please note: when sourcing fish from a supplier, it is important to check the supplier started timing the period of freezing once the fish had hit the target temperature, not as soon as it was been placed in a freezer. That is, once the temperature of the fish reaches -20 °C, the 24-hour timer is started.

Food businesses purchasing raw fish to make sushi must not attempt to freeze the fish to kill parasites themselves unless they can demonstrate to the satisfaction of their Environmental Health Officer (EHO) that their freezer and practices can achieve and maintain the temperature-time freezing requirements stated above. In addition, if carrying out the freezing step yourself you must allow a margin of safety for the food to reach a temperature of -20 °C in all parts of the fish before starting the 24-hour timer.

Businesses carrying out the freezing step themselves must be able to demonstrate how quickly all parts of the fish take to reach a temperature of -20 °C in a freezer maintained at -20 °C. If they cannot do this, they must use a default time of 48 hours (24 hours to reach -20 °C; 24 hours to kill parasites).

Download a template for recording parasite killsA parasite is a small animal that lives on or in a host animal (e.g., fish). Foodborne parasites found in fish can cause human illness. For more information please see our FAQ on Fish Parasites.

- a supplier who can provide documentation that the fish has been caught in a fishing area where parasites are not a health hazard or exclusively reared in an environment that is free from parasites. Please note, a freezing exemption automatically applies to farmed Atlantic Salmon reared in Ireland.

-

Checking your deliveries

- Chilled food should be kept at or below 5 °C

- Frozen foods should be kept at or below -18 °C

- Documentary evidence of maintenance of the cold chain should be kept for chilled foods.

- Reject deliveries of chilled foods where there is evidence that the cold chain has not been maintained.

-

Storage of fish and other seafood

The correct storage of fish is important to control the production of histamine which can cause foodborne illness.

- Store chilled food at or below 5 °C

- Frozen food should be kept at or below -18 °C

- Throw away food or ingredients past their ‘use-by date’

- Sushi/sashimi must be kept separate from raw non-ready-to-eat foods (e.g., raw meat). This avoids cross contamination, i.e. inadvertently contaminating it with food poisoning bacteria from raw food that is intended to be cooked before eating.

- Store sushi/sashimi products in separate compartments on the bottom shelf of the fridge below other ready-to-eat foods in order to avoid potential cross contamination from the raw sushi/sashimi.

- Label with the date of storage and the expiry date

- Foods stored in freezers should be labelled with the ‘date of freezing’ using food grade labels that will not come off in the freezer

For more information see our FAQ on Histamine in Fish and Fishery Products.

-

Defrosting frozen fish

Do:

- defrost frozen fishery products overnight in a fridge between 0-5 °C

- label fish with a ‘date of defrosting’

- have good stock control, i.e., defrost adequate amounts of fish the day before to prevent running out during trading hours

- have good stock rotation, i.e., defrost ‘oldest’ stored fish first

- avoid overfilling the refrigerator

Do not:

- defrost fishery products under running water or in water baths

- defrost fishery products at room temperature

- refreeze previously defrosted fishery products

- freeze fish at the end of its shelf-life

-

Acidification of sushi rice

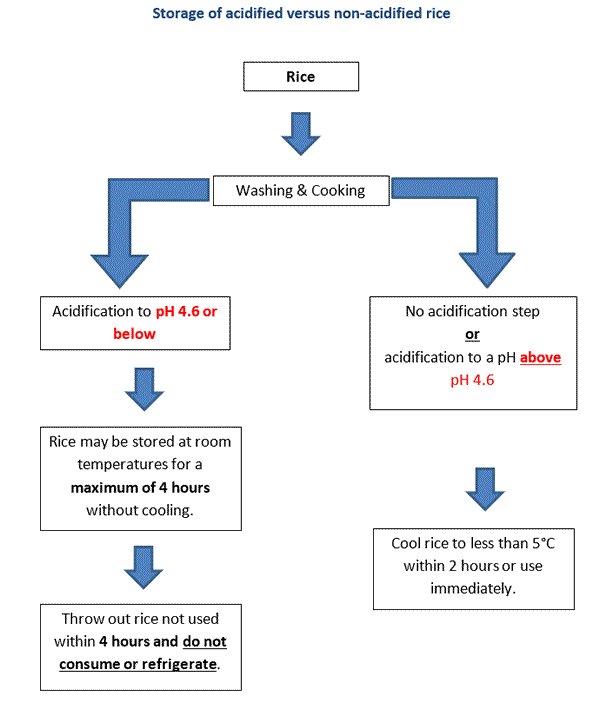

Temperature abused rice i.e. rice that is not cooled down quickly and kept at temperatures above refrigeration temperatures (5 °C) for long periods of time is commonly associated with foodborne illness. Particularly, from the food poisoning organism Bacillus cereus.

Proper acidification of sushi rice by adding a vinegar/salt solution allows hot or warm rice to be kept at room temperature safely for a maximum of 4 hours. This is because bacteria do not like to grow under acidic conditions. However, after this 4-hour period has passed, the rice must be disposed of and should not be refrigerated or consumed by customers or staff.

Food business operators preparing sushi rice have a choice from 2 options. Either:

- Cool rice to 5 °C or below within 2 hours of cooking.

or

- Uniformly acidifying rice to pH 4.6 or below immediately after cooking to allow warm/hot rice to be kept at room temperature for up to 4 hours without the need for cooling.

If opting to acidify rice, food businesses must:

- acidify rice to a minimum target pH of 4.6 or below uniformly throughout all the rice. pH is a measure of how acidic something is. The lower the pH number the more acidic it is

- acidify rice immediately after cooking to pH 4.6 to limit the growth of food poisoning bacteria if present. Mixing in the vinegar solution whilst the rice is still hot also helps the rice to absorb the vinegar/salt solution

- mix sushi rice thoroughly and uniformly with the vinegar solution -there must be no ‘pools’ of vinegar

- use a standardised recipe for their vinegar solution documented in their food safety management system. The recipe should specify exactly how much of the following makes up the total volume of the vinegar solution.

- Specify the amount of salt

- Specify the amount of sugar

- Specify the amount of rice vinega

- use a standardised procedure documented in their food safety management system for mixing the acidification solution with cooked rice. It should specify:

- that the solution is to be added to rice immediately after cooking whilst it is still hot

- the amount of the standardised vinegar solution to be added to a specific volume of rice

- how the rice / vinegar solution should be mixed to achieve uniform acidity

- corrective actions to be taken if pH 4.6 or below is not achieved

- keep records of the time of preparation and the pH of the rice (download a template to record acidification)

- keep records of staff training on acidification recipe and procedure.

- cover acidified rice when not in use

.jpg)

-

Measuring pH

Measuring pH correctly is important to ensure that the critical control of acidifying rice to pH 4.6 or below has been achieved. In order to check the rice has achieved a pH of 4.6 or below, a food business operator must:

- use a calibrated pH meter to check the pH of the rice

- Keep records of the calibration of the pH meter

- Keep records of staff training on calibration of the pH mete

- pH meters should be calibrated according to the manufacturer’s instructions

- Typically, pH meters are calibrated using 2 pH solutions at opposite ends of the pH scale, i.e. using one acid and one base solution

- make sure staff are trained and can show that they know how to use the pH meter in accordance with the manufacturer’s instructions

- Keep records of staff trainin

- ensure the pH meter is clean of any debris, has been sanitised is calibrated with pH solutions according to the manufacturer’s instructions.

- to take a pH reading, take a small sample of rice from the mixed bowl, press the probe into the sample and wait until the pH reading remains stable for at least 5 seconds.

- ensure pH measurements are not taken from any pools of vinegar as this will give a false reading. Sushi rice should be mixed thoroughly so that no ‘pools’ of vinegar remain.

- to ensure uniform acidification to pH 4.6 throughout all of the rice, take several pH measurements from separate areas of the rice.

- Do not ‘mix’ the samples before taking the pH reading. Take each reading as a separate standalone reading

Do not:

- use pH strips or uncalibrated probes to check pH

- use a dirty probe to check pH

- use an uncalibrated pH meter

- take a pH reading directly from a ‘pool’ of vinegar solution

- use a calibrated pH meter to check the pH of the rice

-

Storage & display of sushi/sashimi

General storage

- Display sushi/sashimi products at temperatures at or below 5 °C

- Keep records of the display temperature

- Put in place a documented time control system to ensure that sushi/sashimi products are not stored at room temperatures for a maximum of 4 hours (including preparation time from cooking)

- Keep sushi/sashimi separate from raw non-ready-to-eat foods (e.g. raw meat) to avoid cross contamination.

- Keep sushi/sashimi separate from other ready-to-eat foods to avoid potential cross contamination.

- If making sushi intended for longer term storage (e.g., 2 days), ensure they are made up using cold ingredients. For example, do not mix hot rice with cold fish unless the food is intended to be served immediately to the customer.

- Display sushi/sashimi products at temperatures at or below 5 °C

-

Storage at temperatures above 5 °C

If sushi/sashimi products are stored at temperatures higher than 5 °C:

- for less than 2 hours, they can be placed in the fridge within 2 hours and stored for final use within 2 days.

- for more than 2 hours but less than 4 hours, they should be consumed before the 4-hour time limit is up but should not be returned to the refrigerator.

- for more than 4 hours, they should be thrown away and not consumed by customers or staff.

-

Shelf-life

Sushi/sashimi is a high-risk product because it contains raw fish which can be contaminated with food poisoning microorganisms. We recommend that sushi and sashimi is consumed as quickly as possible after preparation to reduce the risk.

- Sushi/sashimi should be made from the freshest fish possible

- Leftovers can be kept for 2 days if the sushi/sashimi is prepared hygienically and there is strict temperature control (at or below 5 °C)

- Never keep leftovers for 2 days if this will go beyond the foods original ‘use by date’. For example, if the day of preparation is the last day of the fish’s ‘use-by’ date, then you cannot keep the food in a refrigerator for an additional 2 days as the fish’s shelf-life has already expired

Ideally sushi/sashimi dishes should not be prepared and stored from fish nearing the end of its shelf-life, even if the fish is still within its ‘use-by’ date. This is because ‘use-by’ dates on fish are often assigned by the manufacturers on the basis that the product is going to be eaten cooked and not raw. As such, food poisoning bacteria could build up to harmful levels in fish that are approaching the end of their ‘use-by’ date which may cause illness if eaten raw.

Please note, if food businesses are giving a shelf life longer than recommended in this guidance or producing sushi and/or sashimi for other food businesses, then their shelf-life will need to be determined and validated according to the principals outlined in FSAI’s Guidance Note 18.

-

Additional resources